Doubts and Dangers of Disparate Systems in Distribution

The nature of the beast, when it comes to multi-channel distribution services, is an environment that has grown to be out of necessity. It all started with a shipping manifest system. The warehouse grew, and we needed to manage this new warehouse, so we brought in a WMS, which, by the way, had some great features we needed for building our kits. We needed to handle more calls, so the order management system was brought in for consumer direct orders, and then a contact management system for the B2B sales people’s orders. This was so successful for the business overall, but the accounting was becoming a nightmare, so the Accounting people put in some systems they knew already, for receivables and payables, payroll, and oh, a commission system for sales.

Then emails became a thing, so the growing IT Department acquired a customer service email system for that, and eventually found a vendor to do their email marketing. Finally, the Internet happened, so now we keep our inventory on a web store too. Half our customers and orders are coming from there, and going to different places.

When the websites took off, the Purchasing Department had its own PO system brought in, but then they grew and added some hosted forecasting software to use with the Marketing people, who also have a library of spreadsheets and apps for promotion analysis, key code tracking, web specials, and even a cross-sell/up-sell system.

What just happened? Now each of these systems has its own “experts” that the company relies heavily on, but anyone else (especially management) who does not use one particular system every day feels like they are in a foreign country if they need to access it instead of their own department’s system. Management across the board needs to have information from the other systems, so naturally they protect their own data that they have access to. This is their hostage, to use in the daily political negotiations to trade for the data they need from everyone else. Silos of data, built tall throughout the organization, can be a dangerous thing.

I.T. may step in to help with this problem by (guess what?) setting up another system, called a “data warehouse.” A system to sit on top of all the other systems, and pull data from them into one place. (Yes, unfortunately more data feeds, but for the greater good, right?) So eighteen systems now. Much to the dismay of the Accounting department, the numbers never seem to match across systems, but Marketing usually does not mind.

To make matters worse, the eighteen systems we listed above all have monthly or annual maintenance costs, occasional required upgrades just to keep them working properly on the latest version of Windows or with each other, and these crazy “feeds of data” going back and forth all over the place. The I.T. Department is always trying to keep these feeds going successfully, some as if they were donkeys going up a steep mountain trail. Worse yet is when data needs to be entered or regularly corrected in two or more places manually, such as the WMS and the Website.

Is there a better way? What if we combined some of these systems into one “enterprise wide” system (and maybe two or three add-ons)? In most cases, the argument made by the individual departments, for this type of environment, (cherishingly referred to as “best of breed”) is that each system has some compelling feature that we cannot live without (like the WMS’s kitting feature). Features we would lose if we paired down to a single system across several departments. This is rarely true. In most cases, the combined system either already has the feature (if you dig deep enough) or the feature can be added to an enterprise system. But ask yourself, if this compelling feature was reviewed by upper management, could it be deemed a “sacred cow”, which no longer “aligns with the overall goals of our organization?”

Another argument that could be made against having a single system is that we would be putting too many eggs into one basket. If the single system goes down, would the entire organization be stuck? Anyone familiar with the Theory of Constraints understands that any of these systems could be causing a bottleneck. As it turns out, keeping eighteen systems up and running is eighteen times harder than keeping one system up and running. It also turns out that enterprise level systems are built to be more disaster-proof because they know from the ground up how much more they are relied on.

A true enterprise distribution system breaks down the silos of hostage data, requires less overall maintenance costs and resources, and most importantly, it gives management direct access to a clearer, more accurate picture of what is happening at any point in time across all departments, vital for best informed management decision making.

Increase Sales and Build Customer Loyalty with Shipping Subscriptions

Customers all want free shipping. One successful approach is to sell a membership that includes free shipping for one year. Instead of saving up for larger orders to make shipping worthwhile, customers can order what they want when they want it, without thinking about shipping charges. This can be paired with the InOrder Loyalty module, so active members can also earn points, or extra points, they wouldn’t otherwise earn with each order.

InOrder offers a Subscriptions module with a membership option. Businesses typically sell these memberships for a set fee. Shipping can be free or computed at a discount to active members. InOrder will also Email renewal notices or other ads to the members offering special discounts for some or all products. Timing these discounts to go out at different intervals based on RFM is a great way to promote customer loyalty.

The folks at Stewart-MacDonald did just this, with great success. They launched a program called “StewMAX Membership.” For an annual fee, StewMAX Membership provides free standard shipping for one year on all orders to the U.S.. Stewart-MacDonald also extends their free shipping to returns, making purchases risk-free with their 100% Satisfaction Guarantee.

The findings from these programs have been surprisingly successful. Customers on blogs have mentioned that previously they would build a wish list, but under the new program they find themselves ordering any time they need something. This can lead to an increase on small same day orders to the same address, but InOrder allows you to combine shipments for members that are printed on the same day, allowing you to take advantage of the best shipping rate at the time of shipping.

Merchants using this approach have noted success in converting more one-time customers into regular long term customers. With free shipping memberships, customers are much more likely to place frequent orders, ultimately buying more than they would have otherwise, spending more, but also receiving more customer satisfaction.

If You Don’t Know How Your Customers Shop, They May not Find Your Products

We know that if shoppers can’t quickly find what they are looking for on your website, you may as well not offer it, because they will often just give up looking for it, or worse – they will go elsewhere. Giving your customers more options may help them find your products faster.

Web store searches are usually designed by product hierarchy, which is a popular setup. Items are grouped into levels that open as you click to drill-down further. The problem with this is that it’s like going from one room to the next – you usually have to backtrack to enter different rooms. With searches that are designed by product hierarchy, a shopper must keep returning to the “front door” to start looking for the next product.

Your shoppers can find items faster if you provide them with the ability to combine any different criteria, in whatever combinations they choose (even including that hierarchy). This concept is called “Facet Filtering.”

Facet Filtering helps customers fine-tune their search results as they search. Shoppers can make additional selections within current search results based on their individual interests, eliminating the need to sift through too many results all at once. It provides a lot of power for minimal setup.

An example of a search facet can be anything such as color group, size, manufacturer, price range, or whether or not a special feature is included.

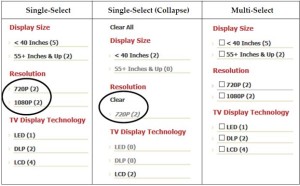

Different Facet Types may be used: Single Select, Single Select/Collapse, and Multi-Select. When Single Select is used, facets appear on the website as links. Only a single facet may be selected per category. When Single Select/Collapse is used, facets appear on the website as links. Only a single facet (subcategory) may be selected per category. When a selection is made, the facet list collapses to only show the selected facet. With Multi-Select, facets appear on the website as checkboxes. Multiple facets may be selected for each category.

Rather than limiting your customers, give them as many ways to shop as possible and let them decide. Then check your analytics – use your InOrder reports and Google Analytics – to learn how your customers shop. InOrder’s superb flexibility allows modifications on the fly, so you can set up products to match how shoppers are searching for them.

Our most notable feedback from merchants using InOrder’s Facet Filtering on their website? Customers frequently searching for products starting with unexpected facets, such as Manufacturer rather than starting with a basic product category. As it turns out, customers often have their own plan they want to follow, and will be more likely to buy what they need on your website if it is flexible enough to let them follow that initial plan.

Finally, accommodating customers’ plans to find their first item will shorten their initial “Add to Cart” times. But customers also can get frustrated if their direct path to the next item they need requires “starting over.” Can they easily edit existing facet filters after placing an item in their cart? If they spent several minutes building a filtered list and now they need three more items from that list, can they add them all or do they need to rebuild the list three more times? Better yet, can they tweak the existing list if needed, without restarting it from the beginning? Check your analytics here as well, to confirm there are no patterns of extra steps they had to take to get to the next item, vs. steps they took on their own due to actual browsing.

With this approach, your abandon rates will be lower than ever, but more importantly, your eCommerce revenue will be better than ever.

InOrder Quick Tip – Quick Printing

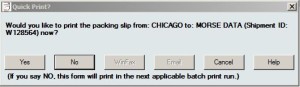

While the vast majority of your orders are normally printed in batch, there may be certain types orders that you print immediately every time you end them. You can set up an InOrder Warehouse Form Type to ask if you want to print when you are ending the order (Quick Printing). The options are Always, Default No, Default yes, and Never.

Quick printing can be tied to certain types of orders. For example, you can define an order class, for rush or special orders, which routes those orders to a Rush Warehouse Form Type that asks about quick printing the order.

Quick Printing may be used for inventory transactions, as well. Other types of transactions that are often quick printed include warehouse transfers, obsolete inventory writeoffs, and kit assemblies.

For more information about quick printing with InOrder, contact sales@morsedata.com.

Get Your Online B2B Presence InOrder

One of the main themes at the IRCE this year was for retailers to add an on-line B2B presence. Through its customer type inheritance capability and its extensive pricing features, InOrder has always supported B2B. InOrder users can build in varying channel segmentation rules and behaviors based on B2B vs. retail in terms of marketing, merchandising, pricing, picking/packing/shipping, customer service, and even contact management for follow-up efforts.

For example, InOrder’s eCommerce module has a built in B2B web site for wholesale orders that can be accessed by your B2B customers. In addition, established business customers can immediately see and search inventory with pricing agreements reflected, and can use their lines of credit when making on-line purchases. They can enter orders using grids. Their shipping arrangements are even automatically applied to web orders. The InOrder “EDI with Customers” Module can be tied in for acknowledgements of web orders, carton license plates, and advance shipping notices.

Designed as a true multi-channel system from the ground up, InOrder is inherently robust in retail and B2B sales, whether in the warehouse, the walkup counter, the web, or “what’s left of the call center” (a phrase mentioned now and again at the show).

Reducing Headcount with InOrder ERP

Nobody talks about “reducing headcount,” but this is a key benefit to a new enterprise software system. If you spearhead a project to buy a new enterprise software system, will it eliminate your position? Will this happen to you or your co-workers?

Now that I have your attention, we need to see why this is important to understand. Typically, the goal of any organization is usually unequivocally to make money for the stakeholders. By definition, this goal can only vary in a non-profit organization, in which case it becomes more difficult to define since non-profits tend to have a lot of volunteers, and each may have their own goals in mind. In either case, it is important that everyone in the organization aligns with the goals of the organization. Of course, it is up to the leadership to find ways to do this.

But whether the organization is trying to make money for investors or to accomplish another goal, someone needs to fund the organization. The ability of the organization is limited by the funding and the organization’s return on investment for this funding. In the case of a for-profit, why would the stakeholders invest in an organization that pays a 10% return when another organization can pay 15%? And for a non-profit, a better return on investment delivers an ability to grow faster with less on-going funding.

The organization cannot just “grow!” Ultimately it helps if everyone in the organization understands that an organization is better off if it can grow its return on investment (ROI).

Focusing on merchants and fulfillment companies, growing ROI requires that an organization do two of the following three things, at the same time:

- Increase Throughput

- Reduce Headcount

- Reduce Inventory

Increasing throughput is the most obvious, as this means processing more orders to increase revenue.

How though, can you increase throughput while reducing headcount or inventory? At first, this seems counter-productive!

The answer is to first realize that we are not talking about simply having layoffs and ordering less inventory. We are talking about Headcount and Inventory as a percentage of the overall throughput. For every additional thousand orders you process, how many additional people need to be there, and how much additional cash needs to be tied up in warehouse inventory (and other commitments such as warehouse space and equipment)?

Let’s say your staff of 10 and inventory levels can handle 1000 orders per week. If you need to double your staff to 20 and double your inventory for an additional 1000 orders per week, the return on investment stays the same.

But if you can increase your throughput by another 1000 orders per week without doubling your staff but you doubled your inventory investment, you’ve improved return on investment. Likewise, if you double your orders per week, double your staff, but don’t need to double your inventory in the warehouse, then you’ve improved your return on investment. For example, a million dollar investment in a company that originally returned a 10% profit of $100,000, just doubled to a two million dollar investment that returns $300,000, or 15%. Each dollar invested by a stakeholder makes a bigger profit each year.

As an organization grows, processes that used to be simple get exponentially more complex. For example:

- Receiving, checking, and storing inventory efficiently

- Processing orders and returns in a way that keeps customers happy

But no matter how efficient these processes can be, the questions that management needs to answer are:

- How much inventory will we need to order, at a minimum, to handle our throughput requirements?

- How few people will we need to handle our throughput requirements?

- Additionally, management needs to make marketing decisions that effectively grow throughput.

For these three reasons, an organization must have an enterprise-wide management system like InOrder, combining data from all areas into a big picture that visualizes what is really happening.

Without this system in place, each department tends to put their own smaller system(s) into place. Each of these subsystems has its own champions, its own learning curve. You might have a website database system and a phone order processing system, feeding a warehouse system, a separate contact management system and an outsourced email marketing system, a customer feedback system, and then some managers with their own spreadsheets or even three ring binders that need to be checked several times a day to answer management decisions.

This is known as a “silo effect” where clusters of private data reside, and are sometimes even guarded from other departments, and in a few cases, held hostage. When this happens, your IT department naturally starts building an array of applets and data feeds to gather all of this information together to enable management decision making.

Your clerical and managerial staff are spending more time collating data into spreadsheets, instead of simply reading the results and then having time to interpret them.

As the organization grows, this ad hoc approach inevitably becomes a house of cards that often relies on one or more key but over-worked and over-stressed IT champions. Rather than leveraging this team to produce the next level of data analysis for decision support, they spend all of their time patching things and just keeping core systems up and running.

With an ERP such as InOrder, your core systems become a utility much like electricity and plumbing, and a candidate for continuous process improvements as new software features are released.

By understanding the need to reduce headcount to improve the stakeholder’s return on investment, we can then see that this often actually means having the ability to grow your organization’s throughput at a faster pace than the corresponding growth in headcount, as well as improving the utilization of existing headcount, in all areas of the organization.

Morse Data Corporation Offers Data Conversion Services!

When you purchase InOrder as your ERP system, our Discovery process has you covered. First, we work with you to fully assess your legacy data, and then we provide you with a detailed Data Conversion Proposal, by phase and category. This allows you to choose precisely which data and level of detail you would like your InOrder system to have when you turn it on.

Our data conversion team experts work with you throughout the process, as we build a reproducible data conversion process that extracts, cleanses, and imports your data. This allows you and your staff to learn and test the new InOrder ERP system using data that you are familiar with. Over the years we have refined this process, and so many of our techniques will surprise you, but they are extremely effective.

Checking the converted data on the new InOrder ERP system not only helps your staff to get familiar with the new system, it helps them feel more at home, and more involved in the conversion process.

We convert Your Data to your new InOrder ERP System!

Are You Realizing the Full Potential of your ERP Software System?

Your company purchased the software, training and setup work was completed, and then it was turned on. A few years have gone by. Now some of the employees and even a few managers have come and gone. Few people in your department remember anything from the training, but you know the basics to get your day to day work done.

The software has a few buttons that you’ve never used. A few are grayed out, and the desk you inherited might even have sticky notes that you don’t understand, like “NEVER PUSH F12!” or “F6Tab F8Total”.

When you connect to the software, it says Copyright © 2009. You realize that was five years ago. OK, maybe it’s not that bad. Let’s say your company does upgrade to the latest version at least once a year. But the process goes like this: The latest version is installed to a Test Environment, where each department assigns someone to follow a testing script that confirms each process can still be performed successfully. Once everyone signs off on this new version, it is installed into the Production Environment. At this point everyone notices some new buttons, but nobody really knows what they do, and so everyone agrees not to press them.

If any of these things have happened to you, then it’s time for an Annual Software Implementation Audit!

The Annual Implementation Audit lasts two to three days. During this time, an Implementation Specialist from the software company visits your office to meet with representatives from each department of your organization, to review your processes that relate to how you use the software system. At this time, employees and especially any managers who have joined the organization can attend some refresher training sessions. This is also a good time to discuss any wish list items, annoyances such as low priority bugs that have never been reported, and especially burning questions about those new buttons that you were told to never press, but you are suspect could solve some problems!

So often, we hear “Why didn’t anyone tell us the system could do this?” Implementation Audits commonly reveal shortcuts that were not being used, but also often find processes being done manually that can be automated, and functions, features, or optional modules that are not being used at all because nobody knew they existed. Instead, these functions are being performed manually, day in and day out, when your software could be doing them for you.

When was your last Annual Implementation Audit? Maybe it is time?

Today’s Winner Is: 3rd Party Fulfillment Companies!

If your company is a 3rdParty Logistics Company (3PL) or a 3rd Party Fulfillment Company (3PF), then you need to do Warehouse Management and Order Fulfillment for each of your clients, and they all have their own unique discounts, charges, and business rules. If you are reading this, then you’ve found the right software to manage this problem! InOrder Software is one database, but it lets you define these rules for each company that you process orders for.

With one login, your call center reps, warehouse people, and accountants can view the data from each company that they want to work with. Your clients can also connect to securely view their own data.

Just a few of the business rules you can define for each company include shipping methods and shipping rates, customer types with pricing and discount rules for B2B and B2C shipments, taxes, warehouse forms and forms routing, integrated shopping cart websites, EDI rules, promotions, integrated loyalty reward programs and gift card processing, payment rules such as PA DSS certified credit card processing, and even installment plans.

Of course, since it is so flexible, there is a lot to learn if you wish to fully take advantage of this. The saying “With great power comes great responsibility” applies here. However, if you are up to this challenge, then the more you learn up front to understand how the rules are defined and what they can be used for, then the more you will be able to take advantage of these virtually endless capabilities.

Just Kitting Around With InOrder

If your company buys lots of parts, and then puts them together before shipping them to customers, InOrder Software is the Warehouse Management System for you!

If your company has trouble keeping enough quantity on hand for your common components, or does not know how many parts to keep in stock, then InOrder is for you.

InOrder solves so many problems for Kit Assembly Companies:

- Managing and tracking work orders to Pre-assemble kits

- Nested kit definitions, with sub-assemblies to sub-assemblies and so on

- Kits on the fly that are built to order

- Easy Kit Definition Access for Customer Service and On-Line, enabling assistance with replacement parts orders

- Part substitutions in a kit or a customer order for replacement parts

- Kit dis-assemblies are also supported, for example, to free up common components needed elsewhere.

- Inventory forecasting and vendor reordering

- Multi-Dimensional Inventory

- Full featured warehouse RF capabilities, including guided or manual put away, and guided cart picking

- Warehouse employee time capture and job costing

- Multi-client support for Kit Service Companies doing Third Party Logistics

InOrder delivers the capabilities you need to improve your warehouse automation, and to increase your warehouse throughput, for the best Return on Investment you will find.