Reducing Headcount with InOrder ERP

Nobody talks about “reducing headcount,” but this is a key benefit to a new enterprise software system. If you spearhead a project to buy a new enterprise software system, will it eliminate your position? Will this happen to you or your co-workers?

Now that I have your attention, we need to see why this is important to understand. Typically, the goal of any organization is usually unequivocally to make money for the stakeholders. By definition, this goal can only vary in a non-profit organization, in which case it becomes more difficult to define since non-profits tend to have a lot of volunteers, and each may have their own goals in mind. In either case, it is important that everyone in the organization aligns with the goals of the organization. Of course, it is up to the leadership to find ways to do this.

But whether the organization is trying to make money for investors or to accomplish another goal, someone needs to fund the organization. The ability of the organization is limited by the funding and the organization’s return on investment for this funding. In the case of a for-profit, why would the stakeholders invest in an organization that pays a 10% return when another organization can pay 15%? And for a non-profit, a better return on investment delivers an ability to grow faster with less on-going funding.

The organization cannot just “grow!” Ultimately it helps if everyone in the organization understands that an organization is better off if it can grow its return on investment (ROI).

Focusing on merchants and fulfillment companies, growing ROI requires that an organization do two of the following three things, at the same time:

- Increase Throughput

- Reduce Headcount

- Reduce Inventory

Increasing throughput is the most obvious, as this means processing more orders to increase revenue.

How though, can you increase throughput while reducing headcount or inventory? At first, this seems counter-productive!

The answer is to first realize that we are not talking about simply having layoffs and ordering less inventory. We are talking about Headcount and Inventory as a percentage of the overall throughput. For every additional thousand orders you process, how many additional people need to be there, and how much additional cash needs to be tied up in warehouse inventory (and other commitments such as warehouse space and equipment)?

Let’s say your staff of 10 and inventory levels can handle 1000 orders per week. If you need to double your staff to 20 and double your inventory for an additional 1000 orders per week, the return on investment stays the same.

But if you can increase your throughput by another 1000 orders per week without doubling your staff but you doubled your inventory investment, you’ve improved return on investment. Likewise, if you double your orders per week, double your staff, but don’t need to double your inventory in the warehouse, then you’ve improved your return on investment. For example, a million dollar investment in a company that originally returned a 10% profit of $100,000, just doubled to a two million dollar investment that returns $300,000, or 15%. Each dollar invested by a stakeholder makes a bigger profit each year.

As an organization grows, processes that used to be simple get exponentially more complex. For example:

- Receiving, checking, and storing inventory efficiently

- Processing orders and returns in a way that keeps customers happy

But no matter how efficient these processes can be, the questions that management needs to answer are:

- How much inventory will we need to order, at a minimum, to handle our throughput requirements?

- How few people will we need to handle our throughput requirements?

- Additionally, management needs to make marketing decisions that effectively grow throughput.

For these three reasons, an organization must have an enterprise-wide management system like InOrder, combining data from all areas into a big picture that visualizes what is really happening.

Without this system in place, each department tends to put their own smaller system(s) into place. Each of these subsystems has its own champions, its own learning curve. You might have a website database system and a phone order processing system, feeding a warehouse system, a separate contact management system and an outsourced email marketing system, a customer feedback system, and then some managers with their own spreadsheets or even three ring binders that need to be checked several times a day to answer management decisions.

This is known as a “silo effect” where clusters of private data reside, and are sometimes even guarded from other departments, and in a few cases, held hostage. When this happens, your IT department naturally starts building an array of applets and data feeds to gather all of this information together to enable management decision making.

Your clerical and managerial staff are spending more time collating data into spreadsheets, instead of simply reading the results and then having time to interpret them.

As the organization grows, this ad hoc approach inevitably becomes a house of cards that often relies on one or more key but over-worked and over-stressed IT champions. Rather than leveraging this team to produce the next level of data analysis for decision support, they spend all of their time patching things and just keeping core systems up and running.

With an ERP such as InOrder, your core systems become a utility much like electricity and plumbing, and a candidate for continuous process improvements as new software features are released.

By understanding the need to reduce headcount to improve the stakeholder’s return on investment, we can then see that this often actually means having the ability to grow your organization’s throughput at a faster pace than the corresponding growth in headcount, as well as improving the utilization of existing headcount, in all areas of the organization.

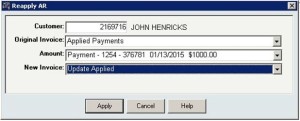

InOrder Quick Tip – Updating an Applied Payment

Has this ever happened to you? You’re applying a payment to multiple invoices, and half-way through, it’s time to go home, or each lunch. Fortunately, InOrder lets you pick up where you left off.

When the entire payment amount is not applied before closing the Reapply A/R window, the balance of the payment is applied to Invoice #0 until the applied payment amount is updated. This feature is used to update the payment applied to Invoice #0.

- From the Original Invoice drop-down list, select “Applied Payments.”

- From the Amount drop-down list, select the payment to update.

- From the New Invoice drop-down list, select Update Applied.

- Click the Apply button.

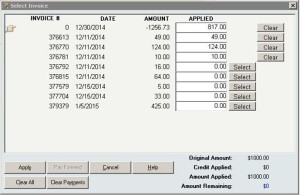

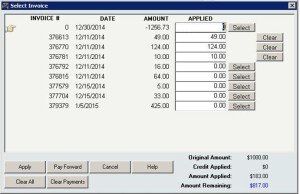

- On the Select Invoice window, the value in the Applied column for Invoice #0 represents the amount of the selected payment to be applied. Click the Clear button to remove the amount applied to Invoice #0. When the amount of the payment applied to Invoice #0 is cleared, it is reflected in the Amount Remaining field.

- Select each invoice to apply.

Protecting Against Theft with ERP Software

Employee theft goes well beyond loss of cash or product to get to your bottom line. It can affect your customers by way of higher prices and inferior shopping experiences, which can have a direct impact on your reputation. Imagine what your customer thinks of your business when he or she is promised an item by a specific date because you think you have it in stock. Although your (paper) records showed you had the item, it was ultimately backordered. Unfortunately, the item was stolen by an employee and you were not aware until the customer was already disappointed.

And speaking of your reputation, you don’t want to invite even more shoplifting because your business is known as an easy target.

Employee theft can also affect other employees. Stealing from you indirectly steals from them. How many times will it happen before other employees question whether you’re competent enough to keep the business strong and safe? After it happens, will you unfairly limit the freedoms of the rest of your staff?

Software Advice™, a consultancy that analyzes inventory management software, recently released the results of a study exploring how inventory management software can detect employee theft.

The survey questioned U.S. retail employees about store types, job titles, inventory management methods, theft perception, and outright stealing from their employers.

According to the report, the National Retail Federation (NRF) estimates that employee theft accounted for almost 44% of total losses for US retailers. Some of the data revealed from responses to the survey from Software Advice™ included the following:

- 85% of national retail chains, 53% of local and regional retail chains, and 37% of small stores surveyed use inventory management software.

- Only 28% of employees whose stores use inventory management software said internal theft is a problem, compared to 37% of employees whose stores use other methods for managing inventory.

- 22% of employees at stores without inventory management software openly admitted to stealing products, compared to 15% of employees whose stores use inventory management software.

As explained in the report, modern inventory management systems can be integrated with other software and hardware to detect suspicious patterns, providing data for management involvement.

For example, when you use a quality ERP system, your inventory availability is tied directly to your order system. The InOrder ERP system includes audit logging, which provides dates, user names, and tasks each user performs. The inventory on hand is tracked for the duration of its time in the warehouse. Any inventory transactions including receipts, sales, returns, as well as all types of adjustments, such as kit assemblies, facility transfers, inter-facility bin moves and replenishments, cycle count adjustments, damaged write-offs, etc. are tracked to allow precise SKU audits. Additionally, full warehouse “snapshots” of quantity and value on hand are taken whenever an accounting period is closed, allowing reports to show beginning on hand, activity, and ending on hand for an accounting period. Inventory accuracy typically approaches 99.9%.

For example, when you use a quality ERP system, your inventory availability is tied directly to your order system. The InOrder ERP system includes audit logging, which provides dates, user names, and tasks each user performs. The inventory on hand is tracked for the duration of its time in the warehouse. Any inventory transactions including receipts, sales, returns, as well as all types of adjustments, such as kit assemblies, facility transfers, inter-facility bin moves and replenishments, cycle count adjustments, damaged write-offs, etc. are tracked to allow precise SKU audits. Additionally, full warehouse “snapshots” of quantity and value on hand are taken whenever an accounting period is closed, allowing reports to show beginning on hand, activity, and ending on hand for an accounting period. Inventory accuracy typically approaches 99.9%.

How else can InOrder help detect theft?

Because InOrder’s Purchasing, Payables, and Inventory systems are all connected, you can compare what was ordered to what was received, to what you are paying your vendors.

The system tracks all purchase orders placed with your vendors, and any subsequent changes to those orders. Inventory receipt transactions are linked to purchase orders, recording what happened to each carton entering the facility. Vendor bills are entered into the system before or after inventory receipt. These bills get linked to the receipt and the purchase order. Any inventory that is received damaged is tracked as it gets routed back to the vendor for credit, and the credits are tracked. These processes enable control over what you receive and approve for payment with your vendors, stopping vendor billing fraud in its tracks.

Then these processes directly feed G/L, thwarting the rogue accountant who tries to skim by charging higher expenses on the G/L than the expenses actually incurred on your vendor bills, and then pocketing the difference.

Finally, InOrder’s tracking auditing enables you to isolate and trace other types of employee theft, such as generation of bogus customer refunds, gift cards, or credit memos issued to friends of employees. Seeing who performed a transaction and when is helpful, but forensic analysis of suspicious transaction patterns in the database can also help to isolate the employee(s) involved.

With a good ERP system, employees discover that they can trust the system, and you in the process. With their trust comes respect and confidence that their jobs will be secure and the business will continue to grow. A good ERP system helps you improve your customers’ shopping experience, achieve their trust that you keep your word about your products, and you take their business seriously.

Take Control of your Organization’s Security with an Incident Response Plan

You’re PCI DSS compliant. Your ERP system is PA-DSS certified. You implemented appropriate security checks in your checkout process. So you have nothing to worry about when it comes to security, right? Maybe…

According to the 2014 Trustwave Global Security Report, 96% of the applications scanned by Trustwave had at least one serious security vulnerability. Further, when detecting a security breach, the Report also revealed that, although 71% of the victims did not detect the breach themselves, doing so would have shortened the containment time from two weeks to 1 day.

An Incident Response Plan may have helped those victims detect those breaches themselves. As explained in Trustwave’s report, an Incident Response Plan is necessary to detect and deter threats. It provides advice for an Incident Response Plan, as well as responses to indicators of compromise. The report outlines these five steps for an Incident Response Plan:

- Train your staff on the best security practices.

- Enforce passphrases or strong passwords (minimum of seven characters and combination of upper/lower case letters, symbols, and numbers). The report revealed that 31% of compromises were caused by weak passwords. Also use two-factor authentication when accessing the network.

- Secure your data. Test and scan to identify and fix flaws early.

- Use penetration testing on your system to identify vulnerabilities and understand how your data can be attacked.

- Plan your response to a breach and practice the Plan.

The Report also revealed that 85% of the exploits detected were of third-party plug-ins. It contains statistics about locations and targeted industries, vulnerable types of applications, top vulnerabilities and severities, methods of intrusion and delivery, regulations, and much more.

Trustwave’s 123-page report is impressive and eye-opening. Knowing your enemy and what they’re planning is critical for defending yourself appropriately. Read the report for a great introduction to understanding security threats, and advice for detecting and responding to them.

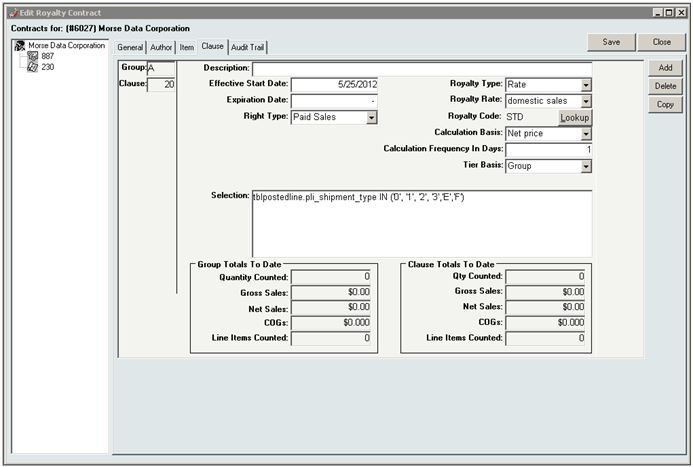

InOrder ERP Offers Sliding Royalty Scales to Adjust Rates Based on Sales

The InOrder ERP [Royalty Contract] window allows you to declare “contract clauses” that select line items that will earn royalties. For example, you can create a clause that pays 10% royalty on “Domestic sales with discount less than 40%” or “All Canada Sales.” InOrder also lets you group these clauses so you can simplify the clause selections. For example, you can have the following group of clauses “Discount greater than 40%,” “Domestic Sales,” and “Foreign Sales.” In this case, any sales with high discounts will pay royalty on the first clause in the group. Otherwise the sale will pay on one of the other two clauses. To illustrate the grouping feature, we can create another clause in a separate group, which earns 1% bonus royalty for any sales that occurred before a certain date. This royalty bonus could be computed on the same contract, next to the other calculation because it is in a separate group. Each clause can earn the author royalty based on a flat percentage / amount, or a sliding scale that adjusts the rate based on sales to date for this specific clause.

This function also allows sliding scales to adjust the rate based on sales to date across all clauses in the clause group, even if some of those clauses pay 0% royalty. This allows you to offer sliding scales that are based on all sales that meet selection criteria for any clause in that clause group, but only pay royalties on the sales selected by that clause itself.

To use this feature, Set the Royalty Type to Rate and select the Tier Basis on the [Royalty Contract] Clause tab. The following selections are available:

- Clause – This selection calculates each clause independently.

- Group – This selection calculates all clauses in a clause group together, which means that sales for all classes in the clause group are used to jump to the next tier in the scale. For example, Group A contains two clauses, 10 and 20. Clause 10 pays x% up to 500 sold and y% over 500, but calculates only on sales in the US. Clause 20 pays X% up to 500 sold and Z% over 500, but calculates only on sales outside of the US. If 300 are sold in the US and 300 outside of the US, Clause 10 pays Y% and Clause 20 pays Z% because the total sold is over 500.

7 Tips for a Better Mobile Checkout Process

Until now, mobile shopping was limited by smaller and smaller screen sizes, but finally users are realizing that bigger screen sizes enable a better mobile buying platform. We believe that this will only increase customer demand where there are better Ecommerce applications.

I think this article by James Bickers is pretty accurate with the five mistakes retailers make with their mobile websites. Those mistakes include:

- Information – Requiring too much entry on the part of the customer increases errors and results in frustration during checkout.

- Lengthy – All the information requested takes too much time to check out, even without making mistakes.

- Intrusive – When a site requires shoppers to register for an account without a guest checkout option, many shoppers will not check out, resulting in abandoned carts.

- Experience – According to the article, 88% of mobile shoppers were not completely satisfied with the mobile shopping experience.

- Security – While shoppers are concerned about the security of their payment information, they also complain about excessive security checks.

So, what do you do to improve your mobile shopping cart? Here are my suggestions:

- Make the checkout process easy – I can make a lot of mistakes entering a lot of information on my phone. What will happen to my order if I fat-finger a key or don’t click something exactly the way the system expects? Will my neighbor get my order? Will I know if it was cancelled? These are real experiences. I just met a neighbor who was nice enough to drive a block away to deliver my package, and a co-worker recently had an order cancelled, but didn’t even know about it until she checked the status and it was too late to re-order in time for Christmas delivery.

- Show your shoppers the checkout flow and let them know what to expect. Try to keep the flow consistent with your online cart.

- Make the checkout process as efficient as possible with as few steps as possible. Keep it simple and quick. Keep page and image loading fast so customers won’t give up on you because it’s taking too long.

- Companies are responding to shoppers’ lack of tolerance when a mobile site requires registration, so your customers have other places to go. If you want registration, at least offer rewards for registering. Another suggestion to consider is that every customer is a guest with a fast and easy checkout, but placing an order creates an account that a customer may or may not choose to access online, now or in the future. If a customer does not “sign in” and just places an order, the system should be smart enough to identify the customer and link to his or her previous orders. However, the ability to see saved information or previous orders, or to place new orders using saved credit card tokens, should always require a secure form of returning user authentication. This does not have to be a password that the user will need to remember. It could be a simple step, such as sending a text or email to the customer’s phone.

- Make sure your mobile shopping cart integrates in real-time with your ERP system so your shoppers don’t get disappointed by unexpected backorders.

- Provide a shipping estimate up front. It’s annoying to have to look for it on a computer, and forget it if I can’t find it while I’m fumbling with my phone.

- Security – Of course I’m concerned about security. I don’t give my credit cards or passwords to anyone, so I do my part. If you say your sight is secure, I’ll believe you – I have to if I’m shopping on my phone, right? So, if I trust my credit card information to you as an Ecommerce shopper, it’s your job to keep it safe. However, I still want you to balance security with a good shopping experience.

For more suggestions on providing a great shopping experience for your customers, or for a free demo, call us at 800-860-9515.

Morse Data Corporation Offers Data Conversion Services!

When you purchase InOrder as your ERP system, our Discovery process has you covered. First, we work with you to fully assess your legacy data, and then we provide you with a detailed Data Conversion Proposal, by phase and category. This allows you to choose precisely which data and level of detail you would like your InOrder system to have when you turn it on.

Our data conversion team experts work with you throughout the process, as we build a reproducible data conversion process that extracts, cleanses, and imports your data. This allows you and your staff to learn and test the new InOrder ERP system using data that you are familiar with. Over the years we have refined this process, and so many of our techniques will surprise you, but they are extremely effective.

Checking the converted data on the new InOrder ERP system not only helps your staff to get familiar with the new system, it helps them feel more at home, and more involved in the conversion process.

We convert Your Data to your new InOrder ERP System!

Welcome Aboard, Joe!

We are pleased to introduce Joe Banass as the newest full time member of our Development Team.

We are pleased to introduce Joe Banass as the newest full time member of our Development Team.

Joe has been with Morse Data as an intern since last May. He completed his finals from DePaul University in November and has earned his Bachelor of Science in Computer Science from the College of Computing and Digital Media.

Joe is one of many college interns who have decided to make Morse Data their home and we are excited to have him on board.

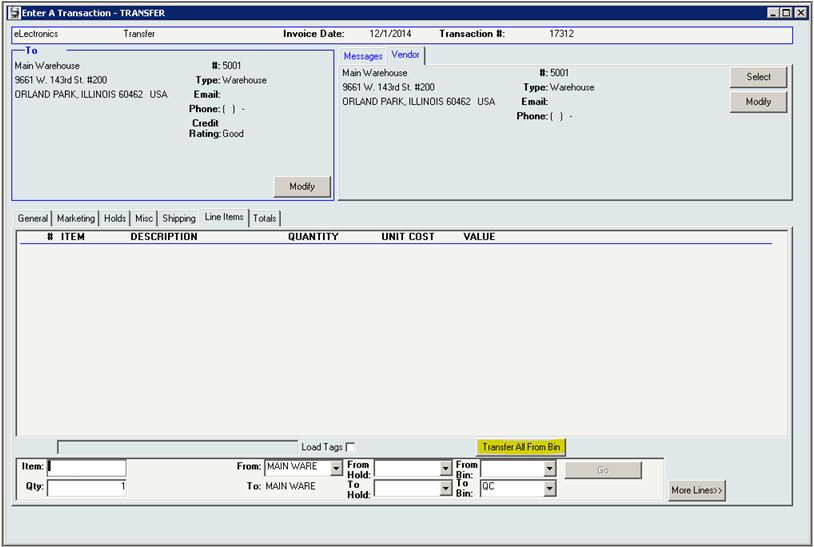

InOrder ERP New Transfer All From Bin Feature Saves Time for Your Warehouse Personnel

When entering Transfer transactions, InOrder users may have already noticed the new Transfer All From Bin button on the Transactions window.

This new function generates an inventory transfer to move all contents from the specified bin to their final destination en masse (rather than individual bin moves) to facilitate guided putaway transactions.

This new function generates an inventory transfer to move all contents from the specified bin to their final destination en masse (rather than individual bin moves) to facilitate guided putaway transactions.

This function is useful for companies that participate in exhibits or use other temporary storage, manually moving stock from one place to another. Now you can update InOrder with the new information with the push of a button.

If you take a trailer out on the road, use Reorder List and Local Reorder Points (as usual) to load the trailer. This loads from multiple bins in the main warehouse to the trailer. When you return to the warehouse and putaway your stock, use the Transfer All from Bin button to generate a transfer to move all stock from the trailer (single location / single bin) back into the warehouse. The Transfer All feature is also useful when you have many items in a bin designated as a “staging area” and you are ready to move them all to the destination. In this case, the staging area bin can be transferred to a remote storage location or exhibit/trailer.

This eliminates the need for individual bin moves and allows transfers across locations from one warehouse to another. You can also print your transaction and use it as a work order.

Previously, when stock was transferred, InOrder identified the From-Bins. Now, you can also select the bin from where you want to transfer your stock, which is also very useful.

How much time will this new feature save you?