Category: Warehouse Inventory Management

There are many ways to improve warehouse efficiency, and many ways to reduce it. Processes can change over time. Your business is constantly evolving and improving, which could result in changing how your ERP system is used. Equally as important as having the best technology is knowing what it can do for your business, and using it to continuously improve your workflows. Not keeping up with these improvements and not keeping your employees trained can result in reduced productivity and efficiency in a warehouse. Here are four examples that can be avoided.

There are many ways to improve warehouse efficiency, and many ways to reduce it. Processes can change over time. Your business is constantly evolving and improving, which could result in changing how your ERP system is used. Equally as important as having the best technology is knowing what it can do for your business, and using it to continuously improve your workflows. Not keeping up with these improvements and not keeping your employees trained can result in reduced productivity and efficiency in a warehouse. Here are four examples that can be avoided.

No Continuous Improvement

Audit your system to review processes that relate to how you use your ERP system. This may reveal shortcuts that were not being used, processes being done manually that can be automated, and functions, features, or optional modules that are not being used at all because nobody knew they existed. Instead, these functions are being performed manually when your software could be doing them for you.

If it’s been awhile since you’ve upgraded your ERP system, consider contacting your vendor to find out what’s new and improved. This is also a good time to discuss any wish list items, and ask questions about new features that could solve some problems.

No Refresher Training

It is beneficial for long-time software users to evaluate how they’re using their software and determine whether improvements can be made in their processes. Consider refresher training if you answer Yes to any of these questions:

- Did any of your employees forget what they need to know from the implementation training?

- Did any of your employees revert to old processes?

- Do you have employees who never received the initial training?

- Is your staff doing manual tasks that can be automated?

No Security Training

Thieves will take advantage of every opportunity available to them. Your employees are an important line of defense against them, unless they don’t know what to watch for, what to protect, or how. POS employees can learn what to do to try to prevent compromised card-reading devices, or how to recognize them, while customer service reps must know not to store sensitive data on their desktops, and all employees should know to check the creditability of Email requests and offers. It’s critical to have a security process in place and make sure your employees know it well.

Training Mistakes

Training can help your staff understand the benefits of your system, both to them and to the company. It can help identify any new processes, new responsibilities, and questions about the system. Training is an opportunity to make sure everyone knows the procedures, their responsibilities in those procedures, and how to accomplish them with your system. Training must be relevant to the users attending, with practice sessions, appropriate training aids, and a resource for follow up.

When you conduct training, be sure to include the following:

- Keep the information relevant to the users attending the training.

- Include practice sessions to follow through the task in detail.

- Provide documentation and training aids.

- Provide a contact for followup questions or additional assistance with the system.

When it’s time to think about your ERP system, give us a call. Morse Data is committed to continuous process improvement. Changes can get out of line, but we help get them InOrder.

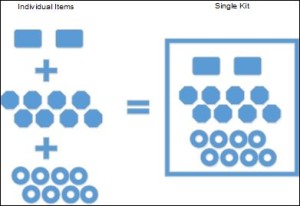

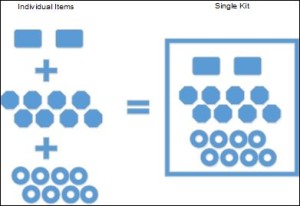

If your company buys lots of parts, and then puts them together before shipping them to customers, InOrder’s Kit Definitions feature will benefit your business. If your company doesn’t always keep enough quantity on hand for your common components, or does not know how many parts to keep in stock, then the InOrder Substitutions feature is for you.

Kit Definitions

The InOrder Kit Definitions feature allows you to assemble multiple items for sale as a single item. With this functionality, you can track the inventory, component assembly and disassembly, sales, and costs of the assembled kit and its component items.

Using InOrder for Kits is great for items you always sell together. It allows you to stock and sell multiple part numbers together under one Top Number. A good example of this would be a Lowering Block Kit, which has u-bolts, blocks, and hardware.

The InOrder Kit Definitions feature provides the ability to:

- Control the inventory and cost for each item individually.

- Base the total cost for the kit on all the items included.

- Discount the retail price (buy in a kit and save).

- Replenish kits based on individual SKUs in stock.

- Disassemble kits when you no longer need them, or to free up common components needed elsewhere.

- Provide easy Kit Definition access to your Customer Service Reps and online, enabling assistance with replacement parts orders.

InOrder Reports for Kit Definitions include the Kit Management Report, which lists kits, their components, and the information about them. Because assembled kits and components are inventory items, they appear on inventory reports and sales reports as any other inventory item. In addition, the InOrder Replenish Report instructs you on how many kits to build based on total number of kits sold and how many of each individual item is in stock. (For example, you can run the report on how many kits were sold in the last 30 days.) Kits are either in stock or out of stock. If one item in the kit is out of stock, the entire kit will be out of stock.

Substitutions

When an out-of-stock inventory item is ordered, you can substitute either a single in-stock inventory item for another brand of the same item, or you can substitute a group of inventory items (Kit-on-the-Fly). This feature works best when you have many items that are typically ordered together, but you need the ability to ship what is in stock. (All items do not have to be in stock at one time to ship, as with Kit Definitions.)

A good example of a Substitution would be an order for the following:

- Interior kit

- Seat Upholstery

- Door Panels

- Headliner

- Carpet Kit

- Rear Seat Shelf

In a Substitution, if the Carpet Kit is out of stock, you can still process the order and ship the remaining in-stock items. The carpet will ship as a backorder (when it is back in stock) and retain the substitution price. InOrder will exchange the price for each item, so it will equal the Substitution Price (buy all the items together and save). In addition, it will break all the items out on an invoice, and you can remove items that may not be needed; the price will adjust.

Unlike Kit Definition, Substitutions do not show in stock or out of stock. Once invoiced, the items are displayed on the invoice with the exchanged price and will either be in stock or backordered (the Top Number will not have inventory).

You can use this feature for Build-to-Order Kits-on-the-Fly as your customers request them, or for Buy-X-Get-Y free offers.

This great feature is very flexible, allowing you to offer up a discounted price for bundled items, and still ship items regardless of inventory status of the items included.

Contact us for more information about how the InOrder Kits and Substitutions features can benefit your business.

You might not think about packing materials every day, but how a product is packed can play a big part in a customer’s perception of a product’s quality. Just as packaging can mean the difference between a customer buying a product or not, if you ship orders, also consider how important your packing material is to your customers.

Here are four simple tips to keeping your packing options competitive:

- Make your packing materials interesting and entertaining to identify your brand. Packing materials also represent your business.

- Educate your customers – Use this as an opportunity to reach out to them. It exceeds their expectations and builds loyalty. It also encourages them to place more orders.

- Advertise your brand – Often, when a package is delivered in a plain, unmarked box or simple padded envelop, it’s a missed opportunity. An unmarked package, which travels across the country, could have been broadcasting the brand it carried all along the delivery route. Inserts and catalogs are great, but using packing materials to encourage your customers to place more orders is brilliance. There are many ideas, such as printing pictures of items you sell with taglines. Because of the expense, it might be worth discussing a cost-sharing arrangement with your vendors to purchase boxes printed with their logo. Likewise, vendors might consider printing boxes with their logos and making them available to their distributors.

- Reduce waste – People don’t usually want to be wasteful, and they’re willing to recycle. Whenever possible, use materials that are easy to reuse and recycle, and your customers will take care of the rest.

As you do for retail customers, give your business clients the same attention. Packing options must be flexible and customizable. Otherwise, you might not have the capability to sell merchandise that clients (or prospective clients) request. You’re not in business to miss out on opportunities, so be sure you have what you need to deliver.

Many reasons can cause problems with a retail business – poor pricing, location, not enough stock, poor planning, all of which can lead to unsatisfactory customer experience and ultimately, failure.

It’s important to understand why a project failed to learn for future success. How can things be different? How can you succeed next time? If you explore reasons for failure, you can use that information to help avoid it in the future.

Poor Location

Location might not seem important, but it is – especially if you’re thinking about international expansion. What do customers in that country expect of their local businesses? What do employees expect? What are the various business and employment laws? If your business is local, it’s crucial to know who your customers are and where they are. Keep these things in mind when deciding where your store will live.

Inappropriate Pricing

Even in your home country, pricing is important for similar reasons – what do customers expect? How far will your customers travel for your products? Can the area support your pricing structure? If your competitors are charging much less, which store will shoppers pick?

Even in your home country, pricing is important for similar reasons – what do customers expect? How far will your customers travel for your products? Can the area support your pricing structure? If your competitors are charging much less, which store will shoppers pick?

Make sure your prices reflect your shoppers’ budgets, and that you can keep up with pricing of your competitors.

Not Enough Stock

Exceptional warehouse control, real-time inventory management, and communication between the distribution center and your ERP system are crucial to maintaining customer satisfaction. Think about it – who wants to shop for groceries in a store that doesn’t keep enough fresh produce in stock? or milk? or bread? Similarly, when shoppers look for clothes, they want to go to stores that carry their styles and sizes.

The other side of this problem is too much inventory because you don’t know how much you need. If you order a million dollars in inventory and don’t sell it in a timely manner, your money is losing interest because it is tied up while inventory sits in the warehouse.

Use an exceptional integrated ERP system to increase productivity. Here are ways your ERP system can help with this.

Inexperienced Partners

There are many things to consider, such as fraud, theft and security, and even training. When working with other parties or their software, unexpected obstacles and delays may be introduced, such as schedule conflicts, terminology misunderstandings, errors, unexpected expenses, and customer service issues. Being on the alert for this and working with experienced businesses and trading partners will go a long way in helping your projects stay within budget and on time.

No Planning

Determine your detailed plan of action items and include the names of the individuals who will be responsible for those tasks. Hold them responsible for the work assigned to them and require a weekly status report on completed tasks and road blocks encountered. This is especially important when implementing critical software for your enterprise.

In more than three decades, the biggest mistake we see companies make is to not create an action plan that covers all aspects of implementation. For more valuable information about Implementing your ERP system, download our “Ten Tips for a Successful ERP Implementation” paper. Whether you’re considering a new ERP system or you’re just beginning an implementation, this paper will help you keep your implementation within budget and on time.

In more than three decades, the biggest mistake we see companies make is to not create an action plan that covers all aspects of implementation. For more valuable information about Implementing your ERP system, download our “Ten Tips for a Successful ERP Implementation” paper. Whether you’re considering a new ERP system or you’re just beginning an implementation, this paper will help you keep your implementation within budget and on time.

We are proud to announce that we have been named a Multichannel Merchant Top Commerce Platform for 2017, part of a list of leading commerce platform providers selected by the editors of Multichannel Merchant. With this listing, users can see InOrder’s featured capabilities, ideal client types, equipment and systems, contact information, and more.

We are proud to announce that we have been named a Multichannel Merchant Top Commerce Platform for 2017, part of a list of leading commerce platform providers selected by the editors of Multichannel Merchant. With this listing, users can see InOrder’s featured capabilities, ideal client types, equipment and systems, contact information, and more.

To see what makes InOrder so special, call us at 888- 667-7332 for a free demo.

Shoppers want to know what they’re buying before they buy it. They want to know if they’ll like a product, how it works, and what others think about it. They also want to know about you.

Embrace your Comparison Shoppers

The InOrder RF communication system efficiently handles inventory through real-time inventory tasks, improving productivity and control for major warehouse functions.

One InOrder site reported that, after rolling out InOrder RF in their warehouse, the inventory receipt processing went from an average of 20 line items per hour to 55 line items per hour, per person, and is now 90% paperless. Some helpful tips include receiving products for many of their vendors that do not provide bar codes by printing a bar coded copy of the vendor PO to use during receiving, using dry-erase boards on their put-away carts, and reviewing a receipt variance report to expose and correct any discrepancies.

InOrder’s RF Communication System supports any internet-capable device. One option includes the Janam XT1 mini tablet, which uses the Android operating system. Another option uses the following configuration: IPod Touch, 5-16 gb ($159, Ebay) with Honeywell Captuvo SL22 Enterprise Sled ($304, Ebay), and Dryrain Technologies’ Enterprise Browser for Captuvo® app ($99).

For more information about InOrder RF, please contact sales@morsedata.com.

Many of InOrder’s functions can be scheduled to run automatically. This is usually done using SQL Server Agent, and can also be accomplished with third party job scheduling tools.

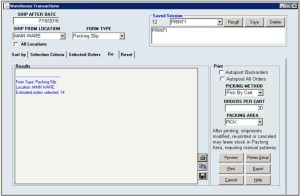

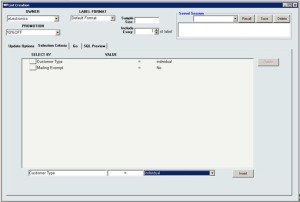

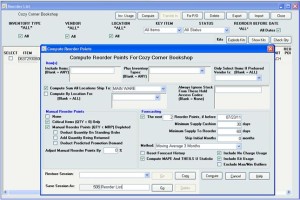

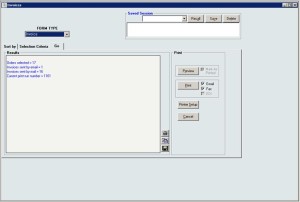

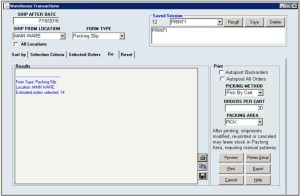

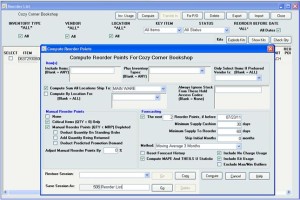

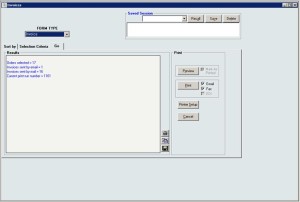

The InOrder Batch Builder Enhancement allows you to schedule several of InOrder’s more complex functions by creating a “Saved Session” consisting of selections and other settings, which can be recalled whenever you want to perform that task in exactly that same manner.

Following is a description of each function that can be run with the InOrder Batch Builder Enhancement:

Warehouse Forms Session – For preparing and/or printing picking or putaway batches.

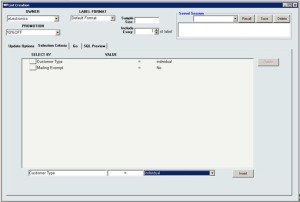

List Creation Session – For generating periodic catalog mailing lists, outbound sales call lists, or Email marketing.

Reorder List Session – For generating reorder lists to place POs with vendors.

Invoice Session – For reproducing printed, EDI, or Email invoices to customers.

Saved sessions for these functions may also be recalled interactively and then processed, or used as a starting point for interactive processing.

For more information about the InOrder Batch Builder Enhancement, contact Morse Data Corporation.

Inventory management has come a long way. In today’s fast paced, Internet-connected world, customers are not willing to wait for a product to be “made to order,” and then shipped in six to eight weeks. They expect it much sooner. This creates the need to stock the product in the warehouse so it is available for immediate shipment when an order is taken. When one firm offers rapid delivery by carrying stock, competitors are generally forced to do the same. And so goes the path of improvement for both businesses and consumers. You want your business to be the one in the lead. Here are five lessons you can teach your competitors about inventory.

Lesson 1 – Keep Fill Rates as High as Possible

If stock is depleted from the warehouse, and a customer’s order cannot be filled within a reasonable or requested amount of time, the customer will often cancel the order and then re-order from a competitor that has stock available.

Lesson 2 – Preventing Attrition is Critical

Once a customer switches to a competitor, it may be much harder to get future orders from that inconvenienced customer. You don’t want to lose the repeat customers that you worked so hard to build up over time.

Lesson 3 – Increased Order Cycle Time Increases Shipping and Fulfillment Costs

For customers who are willing to wait out the backorder fulfillment process, shipping and fulfillment costs will be higher, especially if the order requires partial shipments as stock becomes available. Delayed shipment notices may need to be sent to customers, and the liability for unearned cash prepayments with backorders must be tracked. The cost of filling separate backorders may exceed the profit of the original order, and the only remaining argument for filling the backorder will be to prevent customer attrition.

Lesson 4 – Inventory Turnover is Important

Inventory turnover measures the performance of your investment in your inventory. Carrying too much stock in the warehouse puts a burden on an organization’s cash flow, which can easily outweigh benefits that may be offered for “ordering in bulk” in excess of near-future demand. Carrying too much stock on hand also increases the risks of theft, damage, and obsolescence to inventory on hand during long-term storage.

Lesson 5 – Accurately Forecasting Demand is Critical

Obviously, forecasting is vital for keeping your inventory investment as low as

possible without negatively impacting fill rates. The ability to forecast customer demand accurately is advantageous for obvious reasons:

- It improves customer satisfaction.

- Shipping and fulfillment costs are reduced when orders can be shipped complete at once.

- Inventory quantity on hand is more level, which controls costs and reduces the risks associated with carrying excessive inventory quantities.

Demand forecasts developed within the inventory system must be generally consistent with planning numbers generated by the marketing and other departments. However, your ERP system must use inventory forecast methods that are proven most useful with inventory systems, rather than forecasts generated by marketing or budgeting departments. It is important that inventory forecasts be made by SKU, by warehouse location, and by time unit. Merchandising managers may perform SKU forecasting based on demand history, and market managers may perform forecasting based solely on the predicted sales curve of catalogs. If the marketing department is planning an unusually big promotion and expects to sell three million units of an otherwise unpopular product, and the merchandising department forecasts project a total demand of only one million units, senior management must reconcile these very different visions of the future. While you may influence your customers with pricing, catalogs, and promotions, customers ultimately will order what, where, and when they desire.

The heart of an organization’s forecasting success is knowing how customers will order. The best way to control inventory to your advantage is through an ERP system that plans for future actions of your customer base.

We say a lot about the eCommerce and Customer Service functions of InOrder. Along with everything else, the foundation of the InOrder system is its order processing and inventory, which brings you a number of benefits that permit you to process orders and track inventory under a variety of scenarios. This flexibility keeps inventory accurate at all times and provides the order department with the tools they need for fast and accurate order processing.

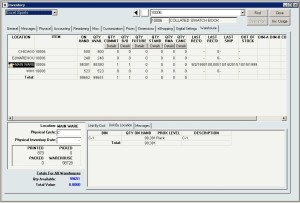

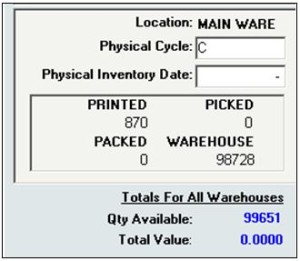

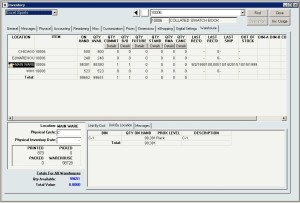

InOrder’s Inventory system is functional and practical. You can check everything you need to know about an item from one convenient window. Check the on-hand quantity, how much is available, backordered, or even when the item was last shipped or received.

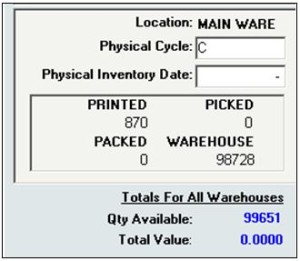

If you need more details for the item at a specific location, you can drill-down to details, check units by cost or location, or see quantities printed, packed, picked, and in the warehouse. The Warehouse shows the sum of the quantity available for stock allocation, plus the quantity allocated to orders being picked, plus the quantity already picked and packed into boxes that are in the process of shipping.

The Warehouse shows the sum of the quantity available for stock allocation, plus the quantity allocated to orders being picked, plus the quantity already picked and packed into boxes that are in the process of shipping.

Call us at 888- 667-7332 for more information about Inventory Management with InOrder, or to request a demo.